Kaizen – De 7 stappen van Continu Verbeteren

Wil je de prestaties van jouw team of bedrijf verbeteren? Zorgen dat klanten en medewerkers meer tevreden zijn? Niet door eenmalig een verbeteractie of project te doen, maar door regelmatig te verbeteren? Lees dan verder hoe het proces van continu verbeteren succesvol aangepakt kan worden.

Maak gebruik van de handige en bewezen PDCA-checklist in de bijlage en laat je inspireren door de cases.

Kaizen – wat is dat?

Kaizen betekent letterlijk Continu Verbeteren en is één van de pijlers van Lean management. Doel is om met veel kleine verbeteringen de productiviteit, kosten, kwaliteit en doorlooptijd te verbeteren. Niet eenmalig dus maar continu. Kaizen werkt effectief bij kleine verbeteringen door de medewerkers zelf. Dus geen groot, lang durend project met een eigen projectteam, maar door de medewerkers zelf aangevoerde verbeteringen.

Kaizen methode werkt als volgt

Om succesvol te zijn in continu verbeteren (Kaizen) zijn de ideeën van medewerkers nodig, de ruimte en support vanuit management en een helder proces.

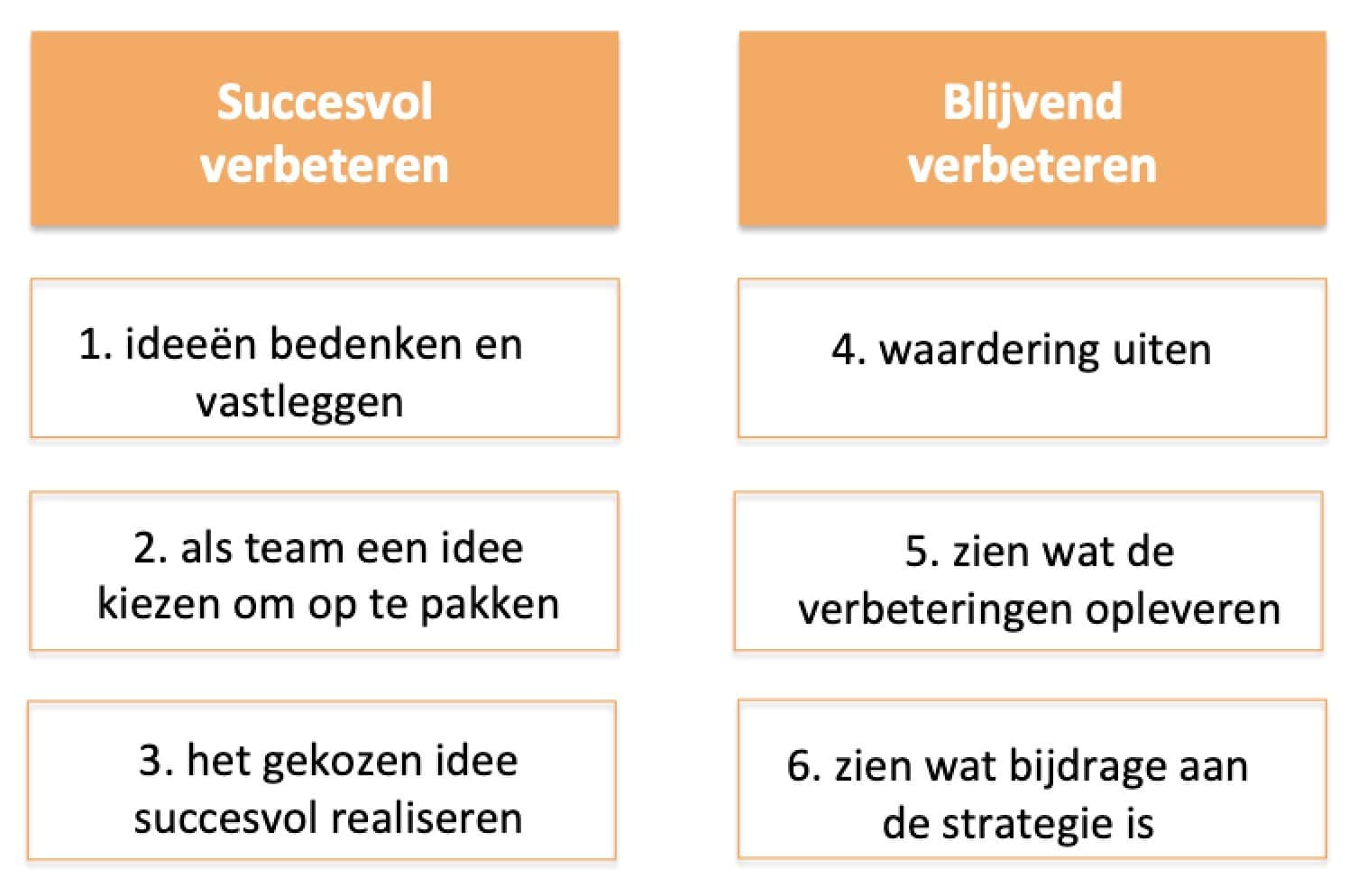

Kaizen bevat 3 belangrijke onderdelen:

- Verbetersuggesties genereren;

- Verbetersuggesties realiseren;

- Monitoren en leren.

Onderdeel 1: Verbetersuggesties genereren

Het proces van continu verbeteren is op hoofdlijnen heel simpel: ideeën genereren, registreren, selecteren, realiseren en feliciteren. Maar er zijn wel een paar netelige punten: in het ideeën genereren zijn er voorwaarden nodig zoals vertrouwen; raken mensen hun baan kwijt?; gaan anderen met een ingebracht idee aan de haal? Daarom is teamontwikkeling zo belangrijk en speelt de kwaliteit van leiding een belangrijke rol. Klik om meer te weten over de “verbeter-idee killers“?

Een ander aandachtspunt is dat medewerkers goed moeten snappen wat de klant wil (Voice of the Customer / VOC) om zo te kunnen bepalen wat Verspillingen zijn of anders gezegd welke activiteiten geen waarde toevoegen voor de klant.

Richting

Ook moet duidelijk zijn waar het bedrijf naar toe wil, het zogenaamde True North. En wat de kernwaarden en strategie zijn. (Voice of the Business / VOB). En de laatste en zeker niet minst belangrijke is Voice of the Employee (VOE).

Verbetersuggesties kunnen in de dagstart genoemd worden of tijdens een speciale bijeenkomst zoals een workshop of brainstorm. Het lijkt erg administratief om elke verbetering vast te leggen, maar juist voor de moraal is het goed om zicht te hebben op hoeveel suggesties succesvol zijn gerealiseerd en bij voorkeur wat ze hebben opgebracht.

Het is raadzaam om alle ideeën en suggesties te registreren hoe vreemd en onhaalbaar ze soms ook mogen lijken.

Onderdeel 2: Verbetersuggesties realiseren

Het realiseren van een verbetersuggestie vindt in teamverband plaats. Hier is diversiteit belangrijk, zodat vanuit meerdere invalshoeken gekeken wordt. Hierdoor ontstaat er niet alleen een beter zicht op het probleem, maar ook een betere oplossing en tevens neemt de acceptatie toe. Effectiviteit is het product van Kwaliteit en Acceptatie (Wet van Maier).

Afhankelijk van de inhoud van de verbetersuggestie kan het verbeterteam bij toepassing van de kaizen methode klein of groot zijn; Het team kan bestaan uit medewerkers van de eigen afdeling of ook van andere afdelingen, leveranciers en/of klanten. Persoonlijke effectiviteit is vaak hoger in kleine teams.

De duur is ook afhankelijk van de moeilijkheid en de urgentie. Indien gewenst kan een speciaal “Kaizen event” plaatsvinden dat bijvoorbeeld 5 volle dagen duurt. Deze aanpak is bedoeld om direct wijzigingen in de procesgang en fysieke opstelling uit te testen en door te voeren.

Onderdeel 3: Monitoren en leren

Het derde onderdeel, na het genereren en realiseren, bevat het monitoren van de voortgang van de individuele verbeteringen (persoonlijke effectiviteit) maar ook hoeveel verbeteringen worden ingediend en succesvol worden gerealiseerd. Vanuit het monitoren kan geleerd worden waarom het ene kaizen event wel succesvol is en de andere niet. Waarom is het ene team wel actief met verbeteringen door te voeren en het andere minder. Deze verzameling van gegevens (process mining) kan middels Coimbee verspreid worden onder het operationeel management.

Wil jij ook het ebook “Succesvol en Blijvend verbeteren” (met 3 praktijk-cases) direct in je mailbox ontvangen?

Wil je meer weten over continu verbeteren en vernieuwen?

Dan zijn dit de leestips:

Medewerkers motiveren en stimuleren elkaar via Coimbee met Like, Follow, Share en Commentaar.

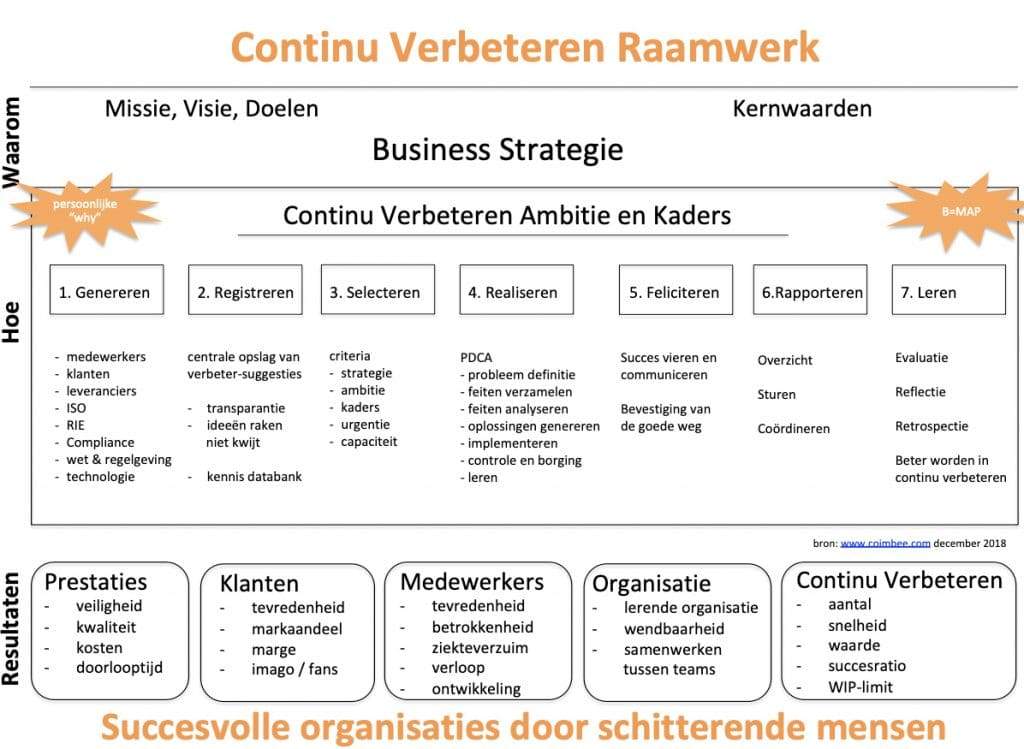

Continu Verbeteren (Kaizen) moet aansluiten bij de strategie van de organisatie.

Kleine verbeteracties, bedacht en uitgevoerd door medewerkers, brengen de organisatie steeds dichter bij het belangrijkste doel van de organisatie.

Elke verbetering zorgt niet alleen voor betere prestaties maar dat er geleerd wordt en dat plezier en betrokkenheid toeneemt. Continu verbeteren draagt ook bij aan teamontwikkeling.

Elke verbetering wordt gestructureerd aangepakt met de PDCA checklist. Een bewezen wetenschappelijke manier om problemen blijvend op te lossen.

Via het digitaal verbeterbord is voor iedereen inzichtelijk in welke fase elk verbeter-idee zicht bevindt.

Het gaat bij continu verbeteren niet om harder werken maar om slimmer werken. En doordat het bij elke verbetering gaat om wat de klant verwacht neemt kennis over de klant verder toe.

Met deze 15 succesfactoren gaat continu verbeteren ook binnen uw organisatie een succes worden.

Six Sigma, Operational excellence, Kaizen en Lean

Six Sigma, Operational excellence, Kaizen en Lean worden vaak in een adem genoemd en er zijn zowel overeenkomsten als verschillen. Wij hebben deze management systemen voor je op een rijtje gezet.

Lean

Lean richt zich op het elimineren van verspillingen en streeft naar zero defects. Lean manufacturing komt van Toyota. Deze werkwijze richt zich richt op efficiency en creëert een flexibele werkomgeving waarbij de klant centraal staat en waarbij men verspilling zoveel mogelijk probeert te vermijden, bijvoorbeeld door middel van een Value Stream Map.

Lean thinking richt zich op het elimineren van verspillingen en streeft naar zero defects. Lean manufacturing komt van Toyota. Deze werkwijze richt zich richt op efficiency en creëert een flexibele werkomgeving waarbij de klant centraal staat en waarbij men verspilling zoveel mogelijk probeert te vermijden. Ook de gemba walk, de Japanse equivalent van Management by Walking Around helpt om efficiency op de werkvloer te verbeteren.

TPM

Een andere vorm van lean thinking is Total Productive Maintenance (TPM). Total Productive Maintenance is een methodiek ter verbetering van de beschikbaarheid van machines en installaties. TPM is ontwikkeld voor optimalisatievan het onderhoud van de installaties en machines en richt zich primair op productiviteitsverbeteringen. Kleine multidisciplinaire verbeterteams vormen een basis van kennis en ervaring van het machinepark. Zij worden aangesteld als eigenaar van de installatie (product owner) en zijn hierdoor direct verantwoordelijk voor de prestaties ervan. Door deze gestructureerde aanpak worden gebreken blootgelegd en wordt de eigen installatie continu verbeterd (Kaizen).

Lean thinking wordt veel middels externe en incompany trainingen geïmplementeerd. Sinds 2020 (Covid-19) worden de trainingen ook gegeven via virtual classrooms. Lean trainingen zijn er op verschillende niveaus, te weten yellow belt, orange belt, green belt en black belt:

- Een Yellow Belt training is een training op het eerste niveau. Men maakt kennis met de Lean theorie en leert vooral om dit toe te passen in de eigen werkomgeving en ontvangt een lean yellow belt certificaat;

- Werknemers met een Orange Belt training kunnen na deze opleiding zelfstandig kleine verbeterprojecten leiden óf bijdragen aan grote Lean verbeterprojecten;

- Een green belt training is geschikt voor mensen die als projectleider voor grotere verbeteringstrajecten aan de gang willen gaan;

- Een Black Belt opleiding is voor lean consultants die complexe veranderingstrajecten in grotere organisaties begeleiden.

- Je kan ook kijken naar de competenties die voor elke rol binnen continu verbeteren nodig zijn. Bekijk daarom het handige overzicht in dit kennisartikel over de 4 rollen als verbeterspecialist.

Kaizen

De Kaizen methode gaat een stap verder en streeft niet alleen naar zero defects maar ook naar voortdurende verbetering. Je blijft de organisatie volgens deze Japanse bedrijfsfilosofie continu verbeteren in kleine stappen. Hierdoor verandert de organisatie op lange termijn steeds en past zich aan aan veranderende omstandigheden. Naast Kaizen management is er Gemba Kaizen, waarbij de voortdurende verbetering specifiek gericht is op de werkplek en dus op initiatieven van de medewerkers. Gemba betekent “de echte plek”, de plek waar het werk wordt gedaan. Medewerkers weten vaak beter wat de problemen op de werkvloer zijn en hoe de problemen opgelost kunnen worden en zodoende slechte resultaten vermeden worden. Gemba Kaizen richt zich dus op continue verbetering op de werkplek met respect voor de mensen op de werkvloer. De echte kaizen expert vindt men vaak ook op de werkvloer.

Six Sigma

Six Sigma is een bij Amerikaanse experts populaire management methode om de winstgevendheid van bedrijven te verbeteren. Six Sigma is gebaseerd op gestructureerd procesmanagement. Veel Amerikaanse bedrijven, waaronder Motorola, General Electric, Ford en Boeing hebben deze management methode met succes ingevoerd. In Nederland is Six Sigma ook populair bij Lean consultants. Lean Six Sigma, de combinatie van deze twee methodes wordt ook vaak geschikt bevonden in het MKB. Maar ook andere combinaties, zoals bijvoorbeeld lean kaizen of kaizen lean komen voor.

Operational Excellence

Operational Excellence in klassieke zin is één van de drie strategieën in het model van Tracey en Wiersema, naast Customer Intimacy en Product Leadership. Basisgedachte is dat je als organisatie moet kiezen op welk vlak je op lange termijn wilt uitblinken. Operational Excellence is in deze definitie een strategie om zo goedkoop mogelijk je product of dienst aan je klant te leveren en toont daarmee verwantschappen met lean management. Al zijn er tegenwoordig ook stromingen die operational excellence niet definiëren als zo goedkoop mogelijk, maar om de producten en/of diensten zo goed mogelijk te maken. Door voldoende verbeteringen door te voeren kiest men er dan voor om een hoger segment of het hoogste segment te bedienen in plaats van te concurreren op prijs.

Nog niet gevonden wat je zocht, zoek dan in andere kennis-artikelen op onze website.

Wil je meer weten over Verbeteren, Lean of Betrokken medewerkers?

Doe dan mee aan ons komende webinar of boek een inspirerende online demo.